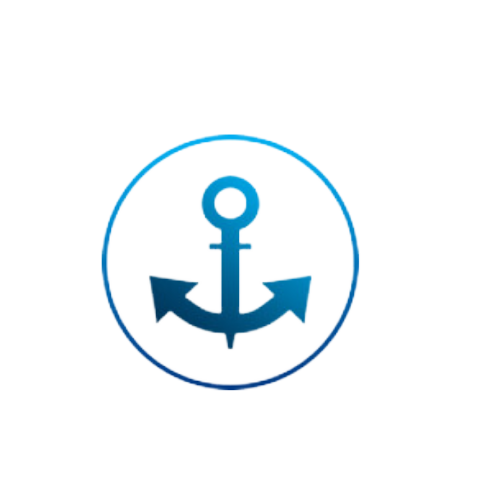

ABOUT Powerfull LUBRICANTS

Powerful lubricants are the lifeblood of machinery, ensuring they operate at peak performance. These high-performance fluids are formulated to excel in extreme conditions, reducing friction, minimizing wear and tear, and prolonging the life of your equipment. Whether it’s in your car’s engine, heavy industrial machinery, or even aerospace applications, powerful lubricants play a critical role in maintaining efficiency, reliability, and safety. Discover how these exceptional lubricants keep the world’s gears turning smoothly.

OUR PRODUCTS AND SERVICES

Developing and marketing technology advanced lubricants according to market trends has always been a priority for Powerfull Lubricants.

Automotive Oils

Industrial Oils

Marine Oils

Greases

ENTERPRISE READY FOR THE FUTURE

Keeping up with innovations in global lubricant markets, Powerful Lubricants has developed and marketed technologically advanced products.

R & D

Powerful Impact

Best Quality

Infrastructure

Industries We Serve:

"Unleash the Power of Performance: Introducing Our Powerful Lubricants!"

“Enhance Efficiency, Extend Machinery Life, and Conquer Any Challenge with Our High-Performance Lubricant Solutions”

Key Features of Powerful Lubricants:

Friction Reduction: One of the primary functions of powerful lubricants is to reduce friction between moving parts. By forming a smooth and continuous film over surfaces, these lubricants minimize the resistance between components, leading to enhanced energy efficiency and reduced heat generation.

Wear Protection: The robust film created by powerful lubricants acts as a protective barrier between surfaces. This shield prevents direct metal-to-metal contact, significantly reducing wear and tear on critical components.

Extreme Temperature Stability: Powerful lubricants can handle extreme temperature variations without losing their effectiveness. Whether it’s scorching heat or freezing cold, these lubricants maintain their performance, ensuring continuous protection for machinery.

- Load-Carrying Capacity: Many industries deal with heavy loads and high-pressure environments. Powerful lubricants are specifically engineered to withstand these intense conditions, making them indispensable for heavy machinery and industrial applications.

Corrosion Prevention: Some powerful lubricants are enriched with additives that protect against corrosion and rust. This feature further extends the life of equipment and machinery, especially in challenging environments.

The Benefits of Using Powerful Lubricants:

Improved Efficiency: By reducing friction and minimizing energy losses, powerful lubricants contribute to improved overall efficiency in various systems and machinery. This efficiency leads to energy savings and reduced operating costs.

Extended Machinery Life: The protective film formed by powerful lubricants shields machinery components from excessive wear and corrosion, allowing them to last longer and reduce the frequency of replacements or repairs.

Reduced Downtime and Maintenance Costs: The use of high-performance lubricants results in less frequent maintenance and downtime for machinery, leading to increased productivity and cost savings.

Enhanced Equipment Performance: Powerful lubricants optimize the performance of machinery, allowing them to operate at their peak, thereby enhancing productivity and output.

Environmentally-Friendly Options: For industries with a focus on sustainability and environmental responsibility, some powerful lubricants are biodegradable and eco-friendly, reducing their impact on the environment.

Selecting the Right Powerful Lubricant:

When choosing a powerful lubricant for a specific application, it’s essential to consider the following factors:

Operating Conditions: Understand the temperature range, load, and pressure conditions under which the lubricant will operate.

Compatibility: Ensure that the lubricant is compatible with the materials and components it will come into contact with.

Industry Standards: Check if the lubricant meets industry-specific standards and regulations.

Additives and Special Features: Some powerful lubricants come with specialized additives tailored for specific purposes, such as extreme pressure protection or corrosion inhibition.

Manufacturer’s Recommendations: Always follow the manufacturer’s guidelines and recommendations for lubrication intervals and application methods.